Market Overview:

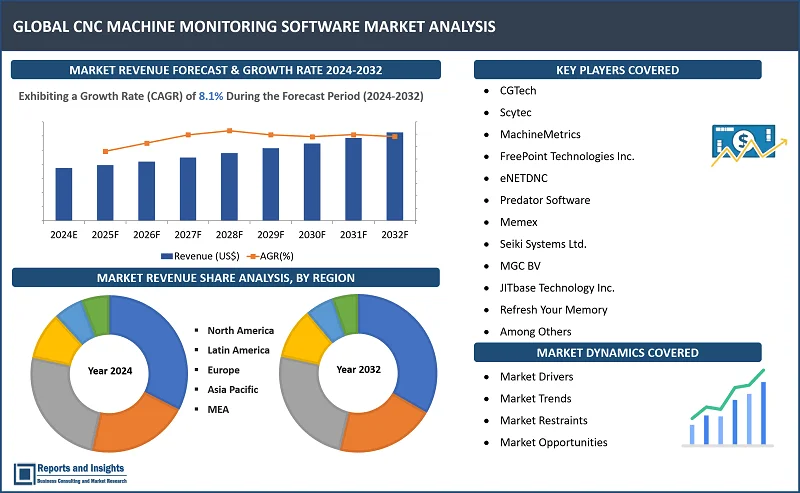

"The global CNC machine monitoring software market size reached US$ 150.7 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 303.7 million in 2032, exhibiting a growth rate (CAGR) of 8.1% during 2024-2032."

|

Report Attributes |

Details |

|

Base Year |

2023 |

|

Forecast Years |

2024-2032 |

|

Historical Years |

2021-2023 |

|

Market Growth Rate (2024-2032) |

8.1% |

Computer Numerical Control (CNC) machine monitoring software is a valuable tool that enables real-time monitoring and analysis of CNC machine performance. By collecting and analyzing data from CNC machines, this software offers several benefits. Primarily, it provides enhanced visibility into machine operations, allowing manufacturers to track productivity, detect inefficiencies, and optimize production processes. Also, CNC machine monitoring software helps identify potential issues or maintenance requirements, minimizing downtime and increasing overall equipment effectiveness. There are different types of CNC machine monitoring software available in the market, ranging from basic monitoring systems to advanced solutions with advanced analytics, predictive maintenance capabilities, and integration with other manufacturing systems.

The global Computer Numerical Control CNC Machine Monitoring Software Market is registering significant growth, driven by increasing adoption of CNC machines across diverse industries. This growth is also attributed to rising demand for real-time monitoring and analysis of machine performance, aimed at enhancing productivity and efficiency.

Preference for CNC machine monitoring software is registering a notable increase as manufacturers focus on optimizing manufacturing processes and minimizing downtime. Advancements in technology, including integration of Machine Learning (ML) and predictive analytics, are further enhancing the capabilities of CNC machine monitoring software. Industry initiatives are focused on ensuring compliance with standards and regulations. Through in-depth analysis and valuable insights, this market research report offers effective solutions for data-driven and efficient manufacturing operations.

CNC Machine Monitoring Software Market Trends and Drivers:

Increasing Adoption of CNC Machines: Increasing adoption of CNC machines across industries is a key factor driving steady demand for machine monitoring software. As more businesses integrate CNC machines into their manufacturing processes, the need for real-time monitoring and analysis to optimize performance and productivity escalates, and this has a positive impact on revenue growth of the CNC machine monitoring software market.

Industry 4.0 and Smart Manufacturing: The global shift towards Industry 4.0 and smart manufacturing practices is supporting demand for advanced technologies like CNC machine monitoring software. These software solutions enable real-time data analytics, predictive maintenance, and improved Overall Equipment Effectiveness (OEE), leading to enhanced operational efficiency and revenue growth.

Focus on Productivity and Efficiency: Manufacturers are increasingly emphasizing on productivity and efficiency improvements to gain a competitive edge. CNC machine monitoring software offers valuable insights into machine performance, downtime analysis, and optimization opportunities, enabling businesses to streamline operations, reduce downtime, and drive revenue growth.

Advancements in Data Analytics and AI: Integration of advanced data analytics and Artificial Intelligence capabilities within CNC machine monitoring software enhances its effectiveness. Machine learning algorithms can analyze machine data to identify patterns, anomalies, and predictive maintenance requirements, leading to better decision-making, increased uptime, and improved revenue generation.

Growing Emphasis on Predictive Maintenance: The shift from reactive to proactive maintenance approaches is gaining traction in the manufacturing sector. CNC machine monitoring software enables predictive maintenance by continuously monitoring machine conditions, detecting potential issues, and scheduling maintenance activities in a timely manner. This trend positively impacts revenue growth by minimizing unexpected downtime and optimizing machine performance.

CNC Machine Monitoring Software Market Restraining Factors:

High Implementation Costs: The initial investment and implementation costs associated with CNC machine monitoring software can be a significant restraint for some businesses. The expenses related to hardware, software licenses, integration, and training can deter adoption, especially for Small And Medium-Sized Enterprises (SMEs), potentially restraining revenue growth.

Limited Awareness and Understanding: Lack of awareness and understanding about the benefits and capabilities of CNC machine monitoring software can impede market growth. Some businesses may be hesitant to invest in these solutions due to a limited understanding of how they can improve productivity, efficiency, and overall manufacturing processes.

Resistance to Technological Change: Resistance to change and reluctance to adopt new technologies can slow down the adoption of CNC machine monitoring software. Manufacturers with traditional practices and legacy systems may be resistant to transitioning to digital solutions, causing a negative impact on revenue growth of the market.

Data Security Concerns: The collection and analysis of real-time data from CNC machines raise concerns about data security and privacy. Businesses may be hesitant to implement CNC machine monitoring software due to worries about potential data breaches, intellectual property theft, or unauthorized access to sensitive manufacturing information.

Complexity of Integration and Scalability: Integrating CNC machine monitoring software with existing manufacturing systems can be complex, particularly in environments with diverse machine types and legacy equipment. Compatibility issues, system integration challenges, and scalability limitations can pose obstacles to adoption, hindering revenue growth.

CNC Machine Monitoring Software Opportunities:

Increasing Demand for Advanced Analytics: Companies operating in the CNC machine monitoring software market have the opportunity to capitalize on the growing demand for advanced analytics capabilities. By providing robust data analytics tools and insights, these companies can help manufacturers optimize their operations, improve productivity, and make data-driven decisions, thereby generating revenue through software licenses and ongoing analytics services.

Integration with Industrial IoT: Integration of CNC machine monitoring software with Industrial IoT Technologies (IIoT) opens up significant revenue streams. By connecting CNC machines to a network and enabling real-time data collection, companies can offer value-added services such as predictive maintenance, remote monitoring, and performance optimization, creating new revenue opportunities.

Subscription-Based Models and Cloud Services: Offering CNC machine monitoring software as a subscription-based service or cloud-based solution provides recurring revenue streams. By providing a scalable and flexible software-as-a-service (SaaS) model, companies can generate revenue through monthly or annual subscriptions, offering continuous support, updates, and maintenance to customers.

Customization and Consulting Services: Companies can differentiate themselves by offering customization services to tailor their CNC machine monitoring software to specific customer requirements. This includes adapting the software interface, incorporating industry-specific features, and providing consulting services for implementation and integration. These value-added services can create additional revenue streams and foster long-term customer relationships.

Expansion into Emerging Markets: With the global CNC machine monitoring software market expanding, companies have the opportunity to explore emerging markets. By targeting regions with growing manufacturing sectors and increasing adoption of CNC machines, companies can expand their customer base and tap into new revenue streams. This may involve local partnerships, localized marketing strategies, and addressing specific market needs.

Market Segmentation:

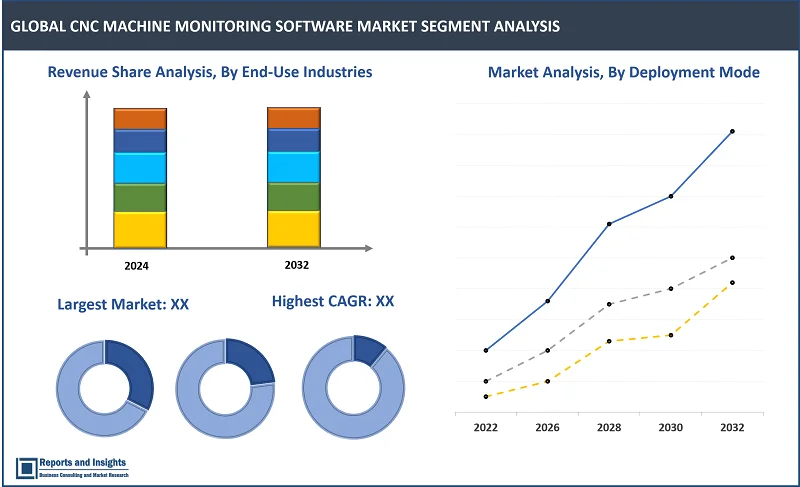

By Deployment Mode:

- On-premises

- Cloud-based

By Functionality:

- Real-time Monitoring

- Data Analytics

- Reporting and Visualization

- Machine Maintenance and Diagnostics

- Alarm and Event Management

By End-User Industry:

- Automotive

- Aerospace and Defense

- Electronics and Semiconductor

- Metal and Machinery

- Medical Devices

- Energy and Power

- Others

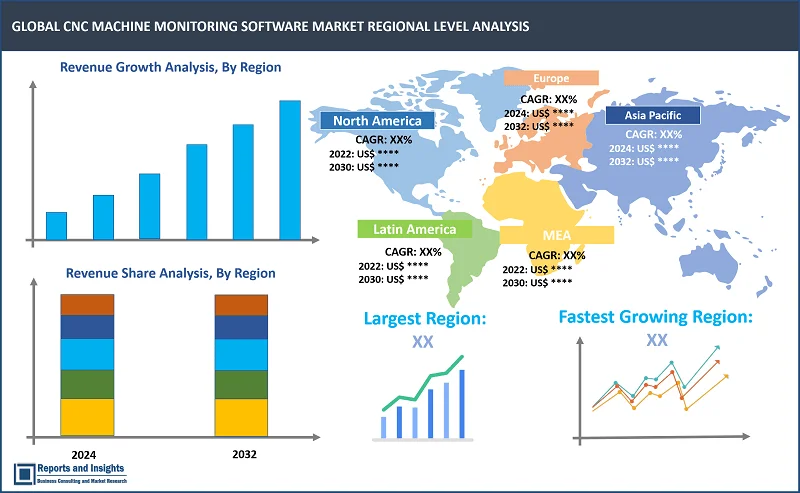

By Region:

- North America

- Latin America

- Europe

- Asia Pacific

- Middle East & Africa

In North America, countries like the United States and Canada exhibit robust demand for CNC machine monitoring software. The region holds a significant market share, driven by strong industrial growth, preference for advanced manufacturing technologies, and government initiatives promoting digital transformation and smart manufacturing. Countries in Europe, including Germany, the United Kingdom, and France, register high demand for CNC machine monitoring software. Steady revenue growth of the market in the region is due to well-established manufacturing sector, rising emphasis on automation, and government initiatives promoting Industry 4.0 and digitalization trends.

Rapid Asia Pacific market share incline is driven by substantial revenue contribution from countries such as China, Japan, and South Korea, which are lucrative markets for CNC machine monitoring software. Rapid industrialization, increasing adoption of CNC machines, and government initiatives are expected to continue to drive market revenue growth.

Leading CNC Machine Monitoring Software Providers & Competitive Landscape:

The competitive landscape of the global Computer Numerical Control CNC Machine Monitoring Software Market is highly dynamic and competitive. Key players in the market focus on differentiating respective brands and solutions by offering advanced analytics, cloud-based solutions, and customization options. The market is characterized by continuous technological advancements, strategic collaborations, and a focus on providing comprehensive and scalable solutions to meet the evolving needs of manufacturers.

Company List:

- CGTech

- Scytec

- MachineMetrics

- FreePoint Technologies Inc.

- eNETDNC

- Predator Software

- Memex

- Seiki Systems Ltd.

- MGC BV

- JITbase Technology Inc.

- Refresh Your Memory

Research Scope:

|

Report Metric |

Report Details |

|

Market size available for the years |

2021-2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024-2032 |

|

Compound Annual Growth Rate (CAGR) |

8.1% |

|

Segment covered |

Deployment Mode, Functionality, End-user Industry, and Regions |

|

Regions Covered |

North America: The U.S. & Canada Latin America: Brazil, Mexico, Argentina, & Rest of Latin America Asia Pacific: China, India, Japan, Australia & New Zealand, South Korea, ASEAN, & Rest of Asia Pacific Europe: Germany, The U.K., France, Spain, Italy, Russia, Poland, BENELUX, NORDIC, & Rest of Europe The Middle East & Africa: Saudi Arabia, United Arab Emirates, South Africa, Egypt, Israel, and Rest of MEA |

|

Fastest Growing Country in Europe |

Germany |

|

Largest Market in Asia Pacific |

China |

|

Key Players |

CGTech, Scytec, MachineMetrics, FreePoint Technologies Inc., eNETDNC, Predator Software, Memex, Seiki Systems Ltd., MGC BV, JITbase Technology Inc., and Refresh Your Memory |

Frequently Asked Question

What are some key trends driving revenue growth of the global CNC machine monitoring software market?

Increasing adoption of advanced analytics, integration with Industrial IoT, emphasis on productivity and efficiency, and advancements in data analytics and AI.

Which industries are the primary consumers of CNC machine monitoring software?

Automotive, aerospace and defence, electronics and semiconductor, metal and machinery, medical devices, energy and power, and more.

How does the competitive landscape of the market look like?

The market is dynamic and competitive, with key players offering advanced analytics, cloud-based solutions, customization options, and strategic collaborations to meet the evolving needs of manufacturers.

What are some major benefits of implementing CNC machine monitoring software?

Implementing CNC machine monitoring software provides benefits such as real-time monitoring, improved productivity and efficiency, and predictive maintenance capabilities.

What are some deployment options available for CNC machine monitoring software?

CNC machine monitoring software can be deployed either on-premises or in the cloud.