Market Overview:

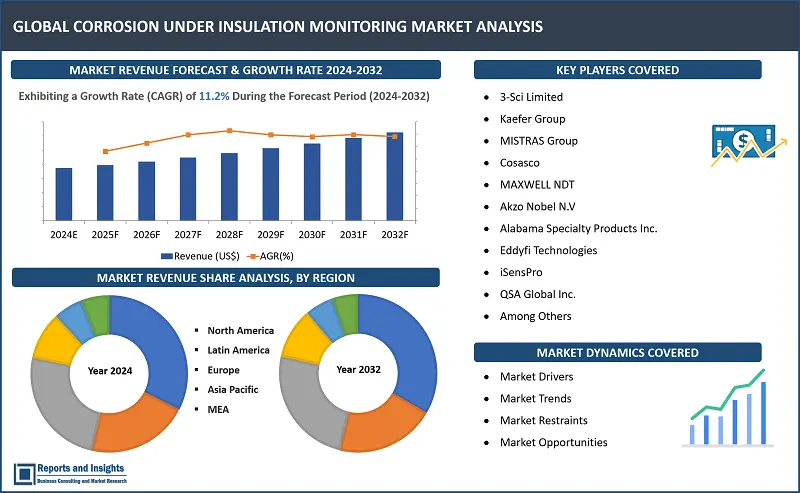

"The global corrosion under insulation monitoring market size reached US$ 97.7 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 254.0 million in 2032, exhibiting a growth rate (CAGR) of 11.2% during 2024-2032."

|

Report Attributes |

Details |

|

Base Year |

2023 |

|

Forecast Years |

2024-2032 |

|

Historical Years |

2021-2023 |

|

Market Growth Rate (2024-2032) |

11.2% |

Corrosion Under Insulation (CUI) refers to a type of corrosion that can happen in thermally insulated pipelines or vessels with inadequate coating. It occurs between the insulation material and the outer surface of the equipment. CUI is a prevalent issue that can affect various types of thermal insulation, such as Rockwool, foam rubber, polyurethane, calcium silicate, and fiberglass.

The oil and gas production industries play a significant role in driving the demand for corrosion monitoring, particularly in the Corrosion under Insulation Monitoring Market. This monitoring method is crucial in preventing premature degradation, ensuring safety, and addressing environmental concerns.

Corrosion-related issues can lead to substantial financial losses due to production interruptions, repair expenses, and unexpected equipment replacements. As awareness about corrosion under insulation monitoring and its importance in preventing failures increases, the market is expected to witness further growth in the coming years.

In addition to the oil and gas sector, the pipeline industry and refineries also contribute significantly to the expansion of the corrosion under insulation monitoring market. These key sectors recognize the value of proactive monitoring to safeguard their infrastructure and prevent costly consequences associated with corrosion-related problems.

Corrosion Under Insulation Monitoring Market Trends and Drivers:

Prevalence of Humid and Tropical Climates: The increasing demand for corrosion under insulation monitoring is driven by the growing economic presence of several countries with humid and tropical climates year-round. In such environments, metals are prone to corrode at a faster rate due to the reaction between oxygen and electrons on the metal's surface in the presence of moisture-saturated air. Metal components are particularly susceptible to rapid corrosion when exposed to prolonged periods of humid air. This type of corrosion is prevalent in regions where the moisture content in the air reaches critical humidity, the point at which water no longer evaporates or gets absorbed from the atmosphere. As a result, there is a rising need for effective corrosion monitoring and prevention methods, such as corrosion under insulation monitoring, to mitigate the detrimental effects of corrosion in these challenging climatic conditions.

Increasing Need for Efficient Processes and Longer Life of The Equipment: The growing demand for efficient processes and extended equipment lifespan has led to the widespread use of corrosion protection coatings, including CUI (Corrosion Under Insulation) and SOI (Splash Zone & Offshore Immersion) coatings. These protective coatings are essential for safeguarding pipelines, equipment, reactors, and storage tanks in industries such as oil & gas and various industrial sectors. Given the nature of operations in these industries, which involve handling hazardous and corrosive chemicals, as well as processes with high temperatures and heat, the equipment is highly susceptible to corrosion and damage. Additionally, the exposure to diverse climatic conditions further impacts the surfaces of reactors and other equipment.

Growing Focus on Asset Integrity: As the importance of safety and dependability in industrial sectors like oil and gas, chemical, and petrochemical is put more and more focus on these factors, there is a growing need for corrosion monitoring solutions that can assure the integrity and lifetime of crucial assets.

Avoiding Expensive Repairs and Downtime: Corrosion-related problems can result in expensive equipment and pipeline downtime, repairs, and replacements. through utilising CUI monitoring technologies, unplanned shutdowns and operational disturbances are prevented through the early detection and prevention of corrosion.

Corrosion Under Insulation Monitoring Market Restraining Factors:

Risk of CUI in Cold Service Insulation: Unlike most insulation systems designed to retain heat, cold service insulation (CSI) presents challenges as it may not effectively protect against heat loss. Without remote monitoring in Corrosion under insulation, there is a risk of heat loss and potential corrosion on assets exposed to high humidity environments. This distinction between hot and cold insulated systems poses a significant factor hindering the market's growth during the forecast period.

Lack of Sufficient Regulatory Mandates: One of the key hindrances to market growth is the absence of comprehensive regulatory mandates in many markets. The lack of sufficient requirements and guidelines may result in slower adoption of CUI monitoring systems. Additionally, a shortage of skilled personnel and technical expertise further limits the widespread implementation and maintenance of these monitoring solutions.

Limited Awareness and Understanding: The lack of awareness and understanding of the risks associated with corrosion under insulation can deter industries from embracing CUI monitoring solutions. As a result, the market growth may be constrained due to the slower adoption rate among end-use industries.

High Installation and Repair Costs: The initial costs involved in installing CUI monitoring systems, as well as potential repair expenses, can be significant. The higher investment required may dissuade some companies from adopting these solutions, thereby impacting market demand.

Corrosion Under Insulation Monitoring Market Opportunities:

Growing Demand for High-Efficiency, High-Performance CUI & SOI Coatings: The rising demand for high-efficiency and high-performance Corrosion Under Insulation (CUI) & Surface Operating Integrity (SOI) coatings is driven by changing operating conditions in various end-use industries, such as oil & gas and marine. These industries require coatings that possess superior properties and efficiency to withstand challenging environments. For instance, the adoption of enhanced oil recovery (EOR) methods in the oil & gas sector necessitates coatings that can endure high temperatures and pressures while providing long-term protection to structures.

Growing Demand from the Oil and Gas Sector: One of the key sectors for corrosion monitoring is the oil and gas production sector. The market for corrosion under insulation monitoring systems is anticipated to be driven by the requirement to prevent corrosion-related failures and guarantee the safety and dependability of pipelines and equipment in this industry.

Growth of the Industrial and Manufacturing Sectors: Thermal insulation is widely used in the industrial and manufacturing sectors, which renders them vulnerable to corrosion under insulation. The use of corrosion monitoring technologies is essential in these sectors as they concentrate on increasing operational effectiveness and reducing downtime to avoid expensive fines and unforeseen equipment replacements.

Asset Integrity Management: Asset integrity management is in high demand as industries realise its importance in extending the operational life and performance of essential assets. Asset integrity management programmes benefit greatly from corrosion under insulation monitoring, which opens up possibilities for its application in many different industrial sectors.

Corrosion Under Insulation Monitoring Market Segmentation:

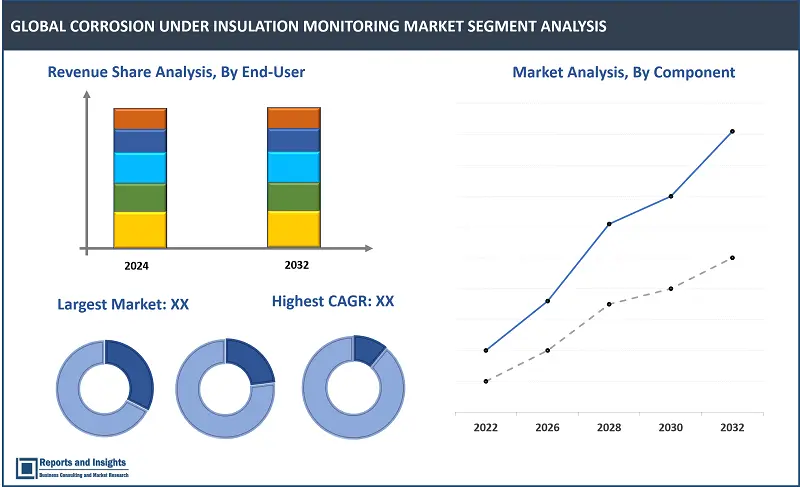

By Component:

- Hardware

- Software

- Services

By End-User:

- Oil & Gas

- Marine

- Chemical & Petrochemical

- Energy & Power

- Food Processing

- Others

By Region:

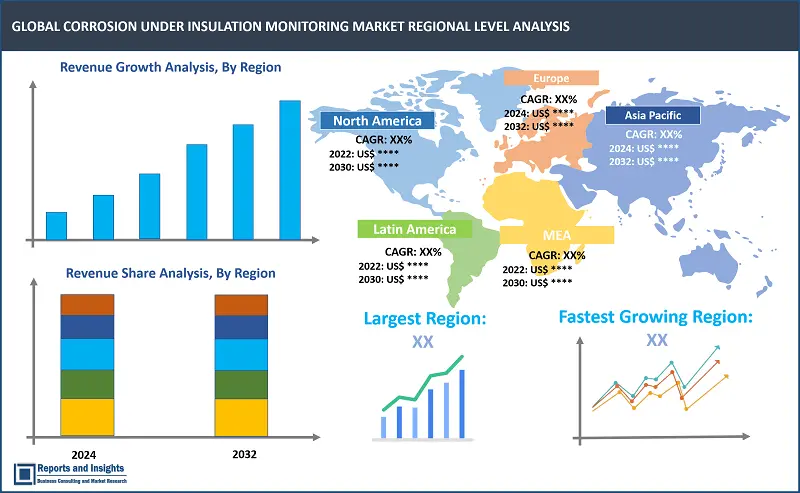

- North America

- Latin America

- Europe

- Asia Pacific

- Middle East & Africa

In Asia Pacific, the corrosion under insulation monitoring market is expected to experience substantial growth at a CAGR of 12% from 2022 to 2032. India, specifically, boasts a robust chemical & petrochemical industry, witnessing increasing investments from both regional and international players. In terms of global trade, India ranks 6th and 9th in imports and exports, respectively, contributing approximately 12.8% in total imports and 12.9% in total exports in 2021. The growth of the industry is attributed to a rise in per capita consumption across the country.

Europe is expected to be a prominent market for corrosion under insulation monitoring due to the presence of well-established industries such as oil & gas, petrochemicals, and manufacturing. These industries extensively use thermal insulation for their pipelines, equipment, and storage tanks, making them susceptible to corrosion under insulation. The region's strict regulations regarding safety and environmental concerns also drive the demand for corrosion monitoring systems. Additionally, the growing emphasis on asset integrity management and preventive maintenance further supports the adoption of corrosion under insulation monitoring solutions in Europe.

The Middle East & Africa region is likely to witness significant growth in the corrosion under insulation monitoring market. The presence of extensive oil and gas production facilities and large-scale industrial projects in the region creates a substantial demand for corrosion monitoring systems. The harsh climatic conditions in certain parts of the region, such as high temperatures and humidity, increase the risk of corrosion under insulation. As a result, industries are increasingly recognizing the importance of implementing corrosion monitoring solutions to ensure the safety and reliability of their assets.

Leading Corrosion Under Insulation Monitoring Providers & Competitive Landscape:

The landscape in the global corrosion under insulation monitoring market is characterized by presence of several key players, thus adding to the level of competitiveness. These companies focus on technological advancements, product innovation, and strategic collaborations to gain a competitive edge. Market competition is driven by factors such as pricing, product performance, customer service, and global market reach, leading to a dynamic and evolving competitive environment.

Company List:

- 3-Sci Limited

- Kaefer Group

- MISTRAS Group

- Cosasco

- MAXWELL NDT

- Akzo Nobel N.V

- Alabama Specialty Products Inc.

- Eddyfi Technologies

- iSensPro

- QSA Global Inc.

Research Scope

|

Report Metric |

Report Details |

|

Market size available for the years |

2021-2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024-2032 |

|

Compound Annual Growth Rate (CAGR) |

11.2% |

|

Segment covered |

Component, End-User, and Regions |

|

Regions Covered |

North America: The U.S. & Canada Latin America: Brazil, Mexico, Argentina, & Rest of Latin America Asia Pacific: China, India, Japan, Australia & New Zealand, ASEAN, & Rest of Asia Pacific Europe: Germany, The U.K., France, Spain, Italy, Russia, Poland, BENELUX, NORDIC, & Rest of Europe The Middle East & Africa: Saudi Arabia, United Arab Emirates, South Africa, Egypt, Israel, and Rest of MEA |

|

Fastest Growing Country in Europe |

Germany |

|

Largest Market in Asia Pacific |

China |

|

Key Players |

3-Sci Limited, Kaefer Group, MISTRAS Group, Cosasco, MAXWELL NDT, Akzo Nobel N.V, Alabama Specialty Products Inc., Eddyfi Technologies, iSensPro, QSA Global Inc. |

Frequently Asked Question

What are some key trends driving revenue growth of the global corrosion under insulation monitoring market?

Humid and tropical climates, increasing need for efficient processes and longer life of the equipment, growing focus on asset integrity and avoiding expensive repairs and downtime.

Which industries are primarily using corrosion under insulation monitoring?

Oil & Gas, Marine, Chemical & Petrochemical, Energy & Power, and Food Processing.

What are some factors impacting the competitive landscape of the global corrosion under insulation monitoring market?

The competitive landscape is influenced by factors such as technological advancements, product innovation, pricing strategies, customer service, global market reach, and strategic collaborations among key players.

What is the expected growth rate of the global corrosion under insulation monitoring market?

The expected growth rate of the global corrosion under insulation monitoring market is projected to be 11.2 % during the forecast period.

What is the market size of the corrosion under insulation monitoring market in 2023?

The market size reached US$ 97.7 million in 2023.