Market Overview:

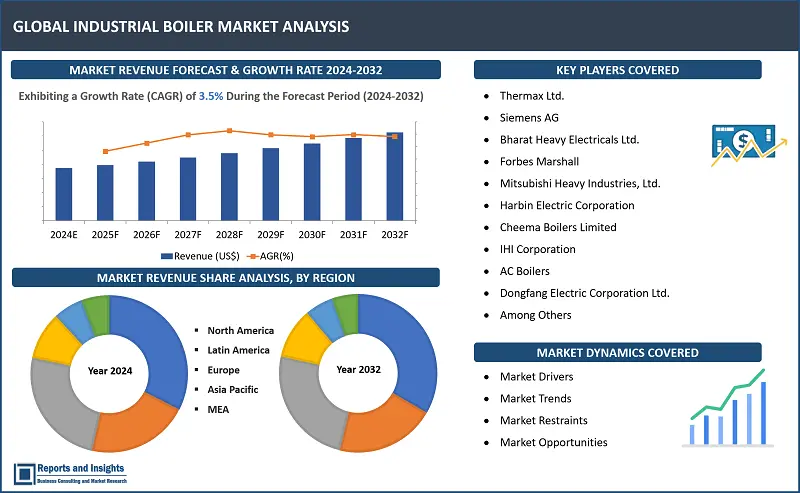

"The industrial boiler market size reached US$ 3.4 billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 4.6 billion by 2032, exhibiting a growth rate (CAGR) of 3.5% during 2024-2032."

|

Report Attributes |

Details |

|

Base Year |

2023 |

|

Forecast Years |

2024-2032 |

|

Historical Years |

2021-2023 |

|

Market Growth Rate (2024-2032) |

3.5% |

Industrial boilers are large, enclosed vessels utilized to heat and circulate water or other fluids for various industrial processes. They are commonly fueled by natural gas, oil, coal, or biomass and operate at elevated temperatures and pressures. The heated fluids are employed for generating steam or hot water, which can then be utilized for heating, power generation, or other industrial purposes. Industrial boilers play a critical role in industries such as manufacturing, chemical processing, and power generation, where the efficient generation of heat or steam is indispensable for operations. Proper maintenance and operation of industrial boilers are crucial to ensure safety, efficiency, and environmental compliance.

The industrial boilers market is experiencing notable expansion, propelled by increasing demand for energy-efficient solutions in sectors like food, chemicals, and refining. This growth is driven by factors such as the adoption of sustainable energy sources, strict environmental regulations, and a focus on reducing operational costs. Furthermore, rapid industrialization and urbanization in emerging markets are contributing to the rising demand for industrial boilers. The market is also witnessing technological innovations, resulting in the creation of advanced boilers that offer improved efficiency and reduced emissions.

Industrial Boilers Market Trends and Drivers:

The industrial boilers market is experiencing notable growth, primarily propelled by key trends and drivers. Increasing industrialization, especially in emerging economies, is boosting the demand for energy, thereby encouraging the uptake of industrial boilers. Stringent government mandates aimed at cutting carbon emissions are also spurring market growth, pushing industries toward cleaner and more efficient boiler solutions. Moreover, the growing emphasis on renewable energy sources and the adoption of digital technologies such as IoT and AI are driving market advancement. Industries are increasingly focusing on enhancing operational efficiency and minimizing environmental footprint, further stimulating market expansion.

The industrial boilers market growth is influenced by several factors such as the growing energy demand from industrial sectors, strict government regulations aimed at reducing carbon emissions, and the adoption of cleaner and more efficient boiler technologies. Furthermore, the market is driven by the integration of digital technologies such as IoT and AI, along with an increasing emphasis on renewable energy sources, which are enhancing operational efficiency and reducing environmental impact.

Industrial Boilers Market Restraining Factors:

Several factors hinder the growth of the industrial boilers market. The high initial investment needed for installation can discourage small and medium-sized enterprises, while alternative heating technologies like heat pumps and solar thermal systems offer more cost-effective and environmentally friendly options in specific applications. Strict government regulations and emission standards require additional investments in pollution control equipment, impacting operational costs. Fluctuations in fuel prices also affect cost-effectiveness. Additionally, the market faces challenges due to the limited availability of skilled workers for operating and maintaining these boilers. Despite these constraints, overcoming these challenges through strategic approaches and advanced technologies could drive market growth.Top of Form

Industrial Boilers Market Opportunities:

The industrial boilers market offers significant opportunities for expansion and enhancement. A key area is the growing emphasis on energy efficiency and sustainability, which is driving demand for advanced, environmentally friendly boiler technologies. Additionally, the trend towards digitalization and the integration of IoT and AI in industrial processes present opportunities for the development of intelligent and efficient boiler systems. Moreover, the expansion of industrial sectors in emerging economies provides a substantial market opportunity, as these regions invest more in infrastructure and industrialization. Collaborations and partnerships among industry players and research institutions could foster innovations and new product developments, further stimulating market growth.

Industrial Boilers Market Segmentation:

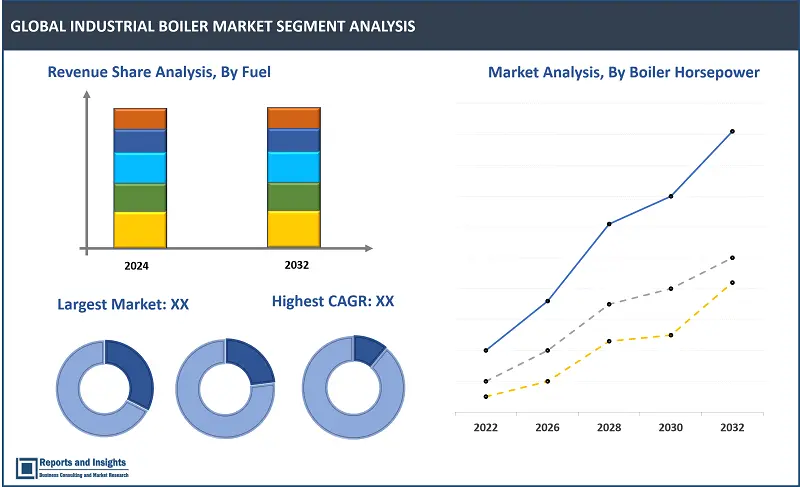

By Fuel

- Natural gas

- Oil

- Coal

The fuel segment comprises of natural gas, oil and coal. Among these, natural gas currently dominates the fuel sub-segment due to its relatively lower carbon emissions, abundance, cost-effectiveness, and versatility. It is favored for its cleaner burning properties compared to oil and coal, making it a more environmentally friendly option. Advances in extraction technologies have made natural gas more abundant and accessible, contributing to its cost-effectiveness. Its versatility allows it to be used in various applications, further solidifying its position as a dominant fuel choice. Additionally, well-developed infrastructure for natural gas, such as pipelines and storage facilities, makes it a convenient and reliable energy source. Overall, these factors have led to natural gas being the dominant fuel sub-segment in the energy sector, with its usage expected to continue growing as countries transition to cleaner energy sources.

By Boiler

- Fire-Tube

- Water-Tube

The boilers segment comprises of fire-tube, and water-tube. Among these, water-tube boilers are the dominant sub-segment in the boiler industry, primarily due to their efficiency, safety features, and versatility. These boilers excel in handling high pressures and varying demands, making them suitable for a wide array of industrial applications. Moreover, water-tube boilers exhibit higher heat transfer rates than fire-tube counterparts, resulting in superior energy efficiency. Their design facilitates easier inspection, maintenance, and cleaning, further enhancing their appeal in industries where reliability and performance are paramount. Overall, water-tube boilers stand out as the preferred choice, valued for their efficiency and reliability.

By Function

- Hot-Water

- Steam

The function segment comprises of hot-water and steam. Among these, steam is the prevailing choice in the function sub-segment, primarily due to their versatility and broad applicability. They are extensively employed across various industries for purposes such as heating, powering machinery, and electricity generation. Their efficiency in heat transfer and capability to operate at high pressures render them ideal for industrial processes requiring elevated temperatures. Moreover, steam boilers can be seamlessly integrated into existing systems, further enhancing their attractiveness. Despite the prevalence of hot-water boilers, particularly in residential and commercial heating, steam boilers maintain their dominance in industrial settings due to their flexibility and efficiency in meeting a variety of operational requirements.

By Boiler Horsepower

- 10-150 BHP

- 151-300 BHP

- 301-600 BHP

The boiler horsepower comprises of 10-150 BHP, 151-300 BHP, and 301-600 BHP. Among these, the 301-600 BHP sub-segment is frequently regarded as dominant because it can meet the needs of medium to large-scale industrial operations while remaining manageable in terms of size and complexity. This range strikes a balance between power output and practicality, making it a popular choice for many industrial applications.

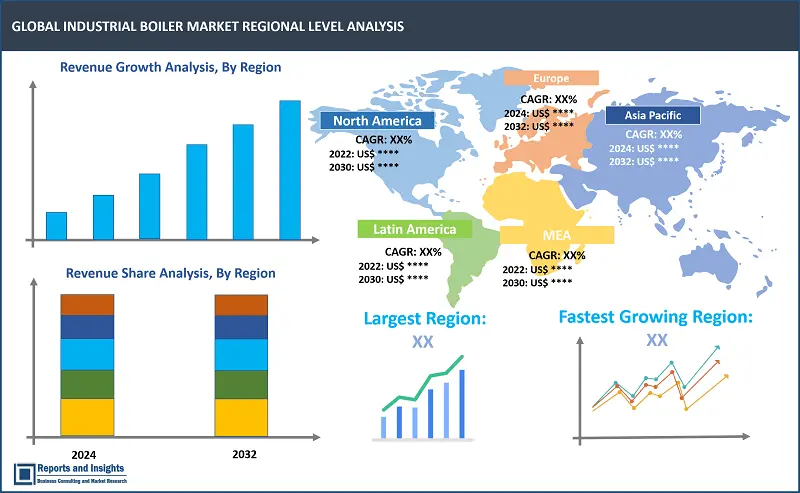

By Region

North America

- United States

- Canada

Europe

- Germany

- United Kingdom

- France

- Italy

- Spain

- Russia

- Poland

- Benelux

- Nordic

- Rest of Europe

Asia Pacific

- China

- Japan

- India

- South Korea

- ASEAN

- Australia & New Zealand

- Rest of Asia Pacific

Latin America

- Brazil

- Mexico

- Argentina

Middle East & Africa

- Saudi Arabia

- South Africa

- United Arab Emirates

- Israel

- Rest of MEA

The industrial boiler market in the Asia Pacific region is witnessing substantial growth driven by factors such as rapid industrialization, urbanization, and a rising energy demand. Countries like China, India, and Japan are at the forefront of this expansion, fueled by the growth of manufacturing, food processing, and chemical industries. Moreover, government incentives aimed at promoting clean energy and replacing outdated and inefficient boilers are also contributing to market growth. The demand for industrial boilers in this region is anticipated to keep rising, fueled by the necessity for dependable and efficient heating solutions across diverse industries.

Leading Industrial Boiler Providers & Competitive Landscape:

The industrial boiler market is highly competitive, with several key players vying for market share and actively engaging in strategic initiatives. These companies focus on product innovation, technological advancements, and expanding their product portfolios to gain a competitive edge. These companies are continuously investing in research and development activities to enhance their product offerings and cater to the evolving needs of customers in terms of efficiency, performance, and sustainability.

These companies include:

- Thermax Ltd.

- Siemens AG

- Bharat Heavy Electricals Ltd.

- Forbes Marshall

- Mitsubishi Heavy Industries, Ltd.

- Harbin Electric Corporation

- Cheema Boilers Limited

- IHI Corporation

- AC Boilers

- Dongfang Electric Corporation Ltd.

Recent News and Development

- January 2023: Babcock & Wilcox Enterprises, Inc. has teamed up with Fidelis, an energy transition company focused on decarbonization through infrastructure development and investments in renewable fuels. Together, they aim to produce clean hydrogen with zero carbon intensity.

Industrial Boiler Research Scope

|

Report Metric |

Report Details |

|

Market size available for the years |

2021-2023 |

|

Base Year |

2023 |

|

Forecast Period |

2024-2032 |

|

Compound Annual Growth Rate (CAGR) |

3.5% |

|

Segment covered |

Fuel, boiler, function, boiler horsepower, and regions. |

|

Regions Covered |

North America: The U.S. Canada Latin America: Brazil, Mexico, Argentina, & Rest of Latin America Asia Pacific: China, India, Japan, Australia & New Zealand, ASEAN, & Rest of Asia Pacific Europe: Germany, The U.K., France, Spain, Italy, Russia, Poland, BENELUX, NORDIC, & Rest of Europe The Middle East & Africa: Saudi Arabia, United Arab Emirates, South Africa, Egypt, Israel, and Rest of MEA |

|

Fastest Growing Country in Europe |

Germany |

|

Largest Market |

North America |

|

Key Players |

Thermax Ltd., Siemens AG, Bharat Heavy Electricals Ltd., Forbes Marshall, Mitsubishi Heavy Industries, Ltd., Harbin Electric Corporation, Cheema Boilers Limited, IHI Corporation, AC Boilers and Dongfang Electric Corporation Ltd. |

Frequently Asked Question

At what CAGR will the industrial boiler market expand?

The market is anticipated to rise at 3.5% through 2032.

How is the boiler segment is categorised in industrial boiler market?

The boiler segment is categorised into fire-tube and water-tube in industry boiler market.

Which region accounted for the largest market share in 2023?

Asia Pacific region accounted for the largest market share in 2023.

What are some key factors driving revenue growth of the industrial boiler market?

Some key factors driving market revenue growth include industrialization, emerging economies, technological advancements, and growing demand in boiler design.

What are some major challenges faced by companies in the industrial boiler market?

Companies face challenges such as regulatory compliance, energy efficiency, fuel price volatility, supply chain disruptions, skill shortages, and aging infrastructure.

How is the competitive landscape in the industrial boiler market?

The market is competitive, with key players focusing on technological advancements, product innovation, and strategic partnerships. Factors such as product quality, reliability, after-sales services, and customization capabilities play a significant role in determining competitiveness.

What are the key participating players in the market?

The major players in the industrial boiler market are Thermax Ltd., Siemens AG, Bharat Heavy Electricals Ltd., Forbes Marshall, Mitsubishi Heavy Industries, Ltd., Harbin Electric Corporation, Cheema Boilers Limited, IHI Corporation, AC Boilers and Dongfang Electric Corporation Ltd.

How can industrial boiler improve energy efficiency?

Industrial boilers can enhance energy efficiency by installing high-efficiency models, optimizing combustion processes, upgrading insulation, and incorporating heat recovery systems.