Market Overview:

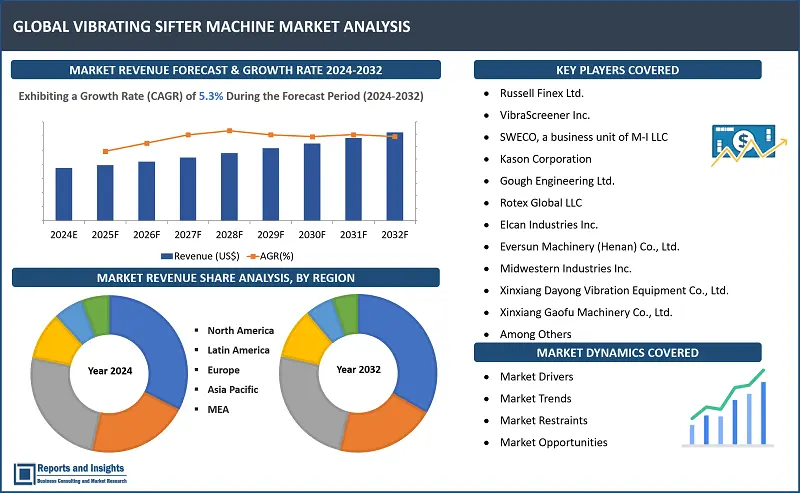

"As per Reports and Insights analysis, the vibrating sifter machine market is expected to grow at a CAGR of 5.3% during the forecast period of 2024 to 2032."

|

Report Attributes |

Details |

|

Base Year |

2023 |

|

Forecast Years |

2024-2032 |

|

Historical Years |

2021-2023 |

|

Market Growth Rate (2024-2032) |

5.3% |

Vibrating sifter machines are utilized across various industries for effective material separation and screening. They find applications in sectors such as food processing, pharmaceuticals, chemicals, mining, and more.

These machines offer several advantages, including efficient particle separation, increased productivity, and improved product quality.

The need to change or replace vibrating sifters may arise due to wear and tear, equipment damage, technological advancements, or evolving industry standards. Different types of vibrating sifters available in the market include rotary, circular, linear, and tumbler sifters, each designed for specific applications and material characteristics.

The global vibrating sifter machine market is registering significant revenue growth due to factors such as rising demand for efficient and reliable separation and filtration solutions across industries, growing focus on product quality and safety standards in food and pharmaceutical industries, and increasing adoption of vibrating sifter machines.

Also, expansion of the industrial sector, especially in emerging economies, is creating new opportunities for market players. Technological advancements, such as integration of advanced features including automated control systems and higher throughput capacity, are further expected to support revenue growth of the market.

Vibrating Sifter Machine Market Trends and Drivers:

Increasing demand for efficient material separation: Rising need for efficient material separation across industries such as food and beverage, pharmaceuticals, chemicals, and mining is driving the vibrating sifter machines market demand. These machines help in removing impurities, ensuring product quality, and increasing production efficiency.

Technological advancements: Advancements in vibrating sifter machine technology, such as the use of advanced sensors, automation, and improved sieve designs, are positively impacting market growth. These advancements enhance the performance, reliability, and accuracy of the machines, leading to increased adoption.

Rising emphasis on hygiene and safety: With strict regulations and quality standards in industries such as food and pharmaceuticals, focus on maintaining hygiene and safety has increased substantially. Vibrating sifter machines play a crucial role in ensuring the removal of contaminants and foreign particles, thereby contributing to product safety and quality compliance.

Growing demand for customized solutions: Customers are increasingly seeking tailored vibrating sifter machines that can meet their specific requirements. Manufacturers are focusing on offering customizable solutions to cater to diverse application needs. This trend is driving market growth and providing opportunities for manufacturers to expand their product portfolio.

Expansion in emerging markets: The global vibrating sifter machine market is registering significant revenue growth in emerging economies due to rapid industrialization and infrastructure development. Countries in Asia Pacific, Latin America, and the Middle East are registering increased vibrating sifter machines market demand, driven by expansion of manufacturing facilities and activities across various industries.

Vibrating Sifter Machine Market Restraining Factors:

High initial investment cost: Vibrating sifter machines can involve significant upfront investment costs, including the purchase of equipment and installation expenses. The high cost of these machines can act as a barrier, especially for small and medium-sized enterprises with limited financial resources, thereby restraining potential market growth.

Maintenance and operational challenges: Vibrating sifter machines require regular maintenance and monitoring to ensure optimal performance. The complexity of these machines and the need for skilled personnel for operation and maintenance can pose challenges for users. Lack of proper maintenance or operational expertise can lead to machine failures and downtime, and this can impacts market growth.

Limited suitability for certain materials: Vibrating sifter machines may not be suitable for handling certain types of materials, such as sticky or wet substances. The design limitations of vibrating sifters can restrict their application in industries where such materials are prevalent. This limitation can affect the adoption of vibrating sifter machines in specific industries and negatively impact market growth.

Environmental concerns: Vibrating sifter machines generate vibrations and noise during operation, which can cause environmental concerns in some settings. Stricter regulations related to noise pollution and occupational health and safety standards may require additional measures to mitigate the impact of vibrating sifter machines. Compliance with such regulations can increase operational costs and pose challenges for market players.

Competition from alternative technologies: The vibrating sifter machine market faces competition from alternative technologies, such as rotary sifters, centrifugal sifters, and other advanced screening solutions. These alternatives may offer different features, efficiency levels, or cost advantages, which can influence the buying decisions of customers and affect market growth for vibrating sifter machines.

Vibrating Sifter Machine Market Opportunities:

Growing demand in the food and beverage industry: The food and beverage industry is a major consumer of vibrating sifter machines for sieving and separating food products. With the increasing demand for processed and packaged food, there is a growing need for efficient and reliable screening solutions. Market players can capitalize on this opportunity by offering specialized vibrating sifter machines designed for food processing applications.

Expansion in the pharmaceutical and chemical sectors: The pharmaceutical and chemical industries require precise and high-quality separation of particles and powders. Vibrating sifter machines with advanced features such as fine mesh screens, multi-deck configurations, and precise control systems can cater to the specific needs of these industries. By targeting these sectors, market players can tap into new revenue streams and leverage the increasing vibrating sifter machines market demand.

Rising adoption in recycling and waste management: Vibrating sifter machines are widely used in recycling and waste management processes to separate different materials and ensure effective waste sorting. With the growing emphasis on environmental sustainability and waste reduction, there is an opportunity for companies to provide innovative vibrating sifter solutions for recycling facilities and waste management centers.

Emerging markets and infrastructure development: Developing regions, particularly Asia Pacific and Latin America, are witnessing rapid urbanization and infrastructure development. This includes the construction of residential and commercial buildings, highways, and other infrastructure projects. Vibrating sifter machines are essential for material separation and quality control in construction applications. By targeting these emerging markets, companies can explore new opportunities and expand customer base.

Technological advancements and customization: Continuous technological advancements are driving the development of advanced vibrating sifter machines with enhanced features and capabilities. Market players can leverage these advancements to offer customized solutions tailored to specific industry requirements. By providing innovative and specialized vibrating sifter machines, companies can attract customers looking for efficient and reliable screening solutions, thereby generating additional revenue streams.

Vibrating Sifter Machine Market Segmentation:

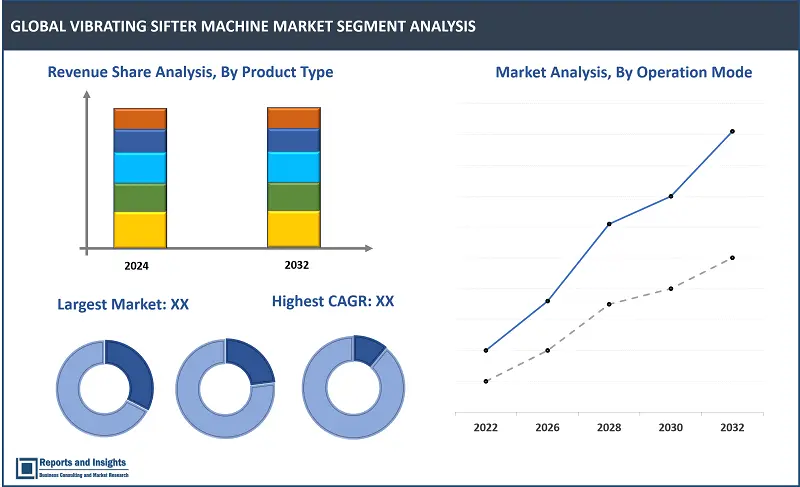

By Product Type:

- Rotary Vibrating Sifter Machine

- Circular Vibrating Sifter Machine

- Linear Vibrating Sifter Machine

- Tumbler Vibrating Sifter Machine

By Operation Mode:

- Manual Vibrating Sifter Machine

- Semi-automatic Vibrating Sifter Machine

- Automatic Vibrating Sifter Machine

By End User:

- Food and Beverage Industry

- Pharmaceutical Industry

- Chemical Industry

- Mining and Metallurgy Industry

- Cosmetics and Personal Care Industry

- Others

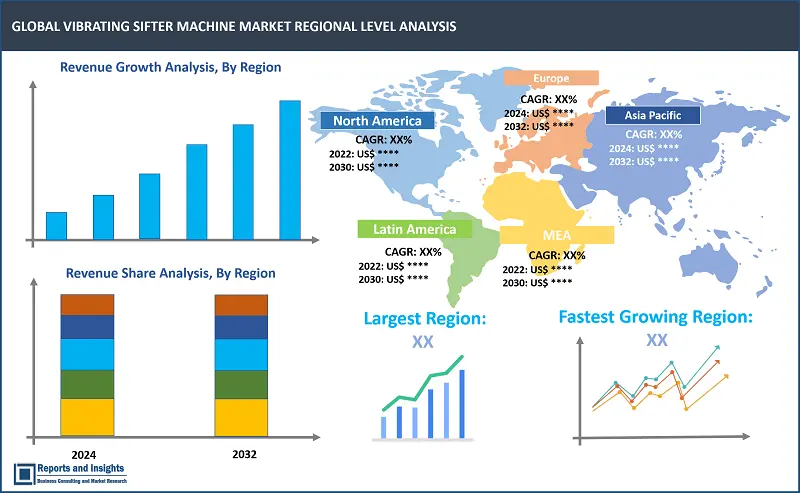

By Region:

- North America

- Latin America

- Asia Pacific

- Europe

- Middle East & Africa

Demand for vibrating sifter machines varies across different regions, reflecting the specific needs and industrial landscape of each area. In North America, industries such as food and beverage, pharmaceuticals, and mining drive the demand for efficient screening equipment. The region has a well-established manufacturing infrastructure and intense competition among both local and international manufacturers. European markets prioritize vibrating sifter machines that comply with stringent regulatory standards and offer high accuracy in particle separation. The region's well-developed manufacturing sector and focus on quality and safety contribute to the market growth. In the Asia Pacific, rapid industrialization, infrastructure development, and investments in manufacturing sectors fuel the demand for vibrating sifter machines.

The market is characterized by a large number of local and international manufacturers, with cost-effectiveness and versatility being key consumer preferences. Latin America and the Middle East & Africa regions experience growing demand for vibrating sifter machines in industries like food processing, mining, construction, and recycling. Consumers in these regions prioritize robust performance and cost-effective solutions capable of withstanding challenging environmental conditions. The market in these regions is influenced by trade policies, import-export regulations, and local manufacturing capabilities.

Leading Vibrating Sifter Machine Providers & Competitive Landscape:

The global vibrating sifter machine market is highly competitive, with a fairly large number of key players leveraging opportunities to account for maximum market share. Major companies in the industry focus on product innovation, technological advancements, and strategic partnerships to gain a competitive edge. These companies invest in research and development activities to introduce advanced vibrating sifter machines with improved efficiency, accuracy, and durability. Companies also engage in mergers, acquisitions, and collaborations to expand their product portfolios and global presence. The market is characterized by intense competition, with companies striving to offer customized solutions to meet specific customer requirements. The competitive landscape is further influenced by factors such as pricing strategies, after-sales services, and customer relationships, as companies aim to differentiate themselves and establish a strong market position.

Company List:

- Russell Finex Ltd.

- VibraScreener Inc.

- SWECO, a business unit of M-I LLC

- Kason Corporation

- Gough Engineering Ltd.

- Rotex Global LLC

- Elcan Industries Inc.

- Eversun Machinery (Henan) Co., Ltd.

- Midwestern Industries Inc.

- Xinxiang Dayong Vibration Equipment Co., Ltd.

- Xinxiang Gaofu Machinery Co., Ltd.

- Virto-Cuccolini S.r.l.

- Others

Research Scope:

|

Report Metric |

Report Details |

|

Market size available for the years |

2021-2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024-2032 |

|

Compound Annual Growth Rate (CAGR) |

5.3% |

|

Segment covered |

By Product Type, By Operation Mode, By End-User, and By Region |

|

Regions Covered |

North America: The U.S. & Canada Latin America: Brazil, Mexico, Argentina, & Rest of Latin America Asia Pacific: China, India, Japan, Australia & New Zealand, ASEAN, & Rest of Asia Pacific Europe: Germany, The U.K., France, Spain, Italy, Russia, Poland, BENELUX, NORDIC, & Rest of Europe The Middle East & Africa: Saudi Arabia, United Arab Emirates, South Africa, Egypt, Israel, and Rest of MEA |

|

Fastest Growing Country in Europe |

Germany |

|

Largest Market in Asia Pacific |

China |

|

Key Players |

Russell Finex Ltd., VibraScreener Inc., SWECO, a business unit of M-I LLC, Kason Corporation, Gough Engineering Ltd., Rotex Global LLC, Elcan Industries Inc., Eversun Machinery (Henan) Co., Ltd., Midwestern Industries Inc., Xinxiang Dayong Vibration Equipment Co., Ltd., Xinxiang Gaofu Machinery Co., Ltd., Virto-Cuccolini S.r.l., and amongst others. |

Frequently Asked Question

At what CAGR will the vibrating sifter machine market expand?

The market is anticipated to rise at 5.3% through 2032.

What are some major opportunities for vibrating sifter machine providers?

Growing demand in the food and beverage industry, and emerging markets and infrastructure development are some of the major opportunities in the market.

What are some key factors driving revenue growth of the vibrating sifter machine market?

Some key factors driving market revenue growth include Increasing demand for efficient material separation, rising emphasis on hygiene and safety, and expansion in emerging markets.

What are some major challenges faced by companies in the vibrating sifter machine market?

Companies face challenges such as high initial investment cost, maintenance and operational challenges, and limited suitability for certain materials.

Who are the major players in the vibrating sifter machine market?

The major key players are Russell Finex Ltd., VibraScreener Inc., SWECO, a business unit of M-I LLC, Kason Corporation, Gough Engineering Ltd., Rotex Global LLC, Elcan Industries Inc., Eversun Machinery (Henan) Co., Ltd., Midwestern Industries Inc., and others.